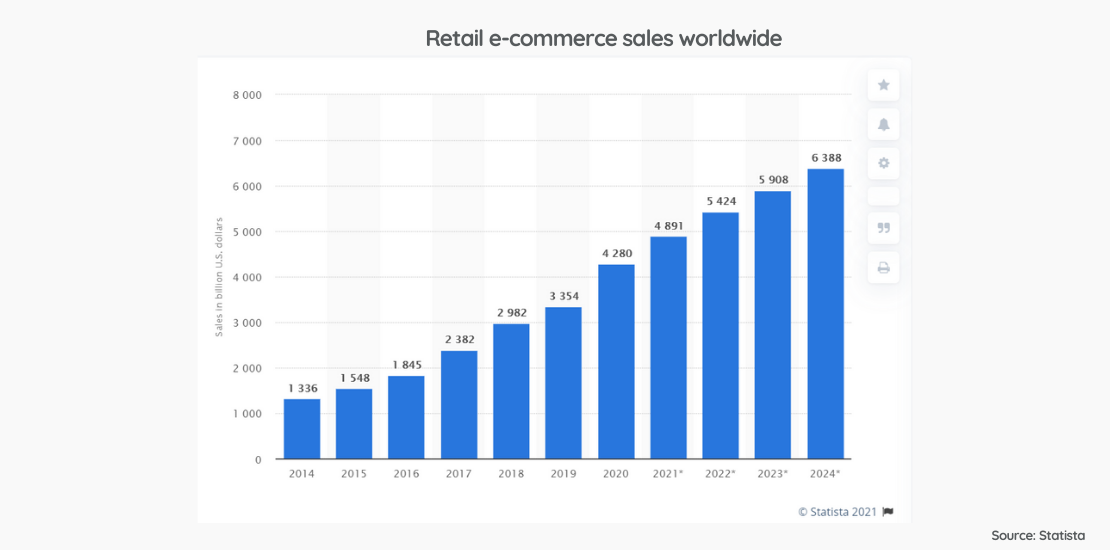

E-commerce channels are no longer just a component of the ecosystem but are at the center of operations.

This volume and improved customer demand create a need for more complicated e-commerce technologies. Handling multiple channels efficiently and managing successful omnichannel operations is a strategic and challenging issue to tackle. While setting up the experience you will offer to the user is part of this challenge, the other is building a system capable of smoothly managing supply operations in the background. Although the point experienced by the consumer is the tip of the iceberg, you have to build and manage a very complex structure behind the scenes. One of the crucial components of this structure is inventory management.

For many retailers, during Covid-19, providing better stock availability has been a positive factor to gain a competitive advantage in the consideration of customer preferences, says Gartner. With the pandemic, the access of offline store and warehouse stocks through online stores has been one of the most striking changes for brands considering the shutdown of offline stores and its impact on the economy. However, only integrating online and offline stocks may not be sufficient. To increase the efficiency of your operations, advanced management is a necessary phenomenon.

In order to reach targeted sales through online channels, having a sufficient inventory level is an important matter. Not providing your customers with products which were sold out at the online store but are present in the general stock can result in incomplete purchases. In order to avoid these undesirable situations, determining a minimum stock level is a common solution.

The minimum stock level is the lowest level of the products’ stock that you determine for each item. The main reason to determine a minimum stock level is to ensure that stocks are sufficient in case of multiple sales per second from different channels and be able to fulfill every order. However, for brands that have a wide range of products it is not sufficient to set a minimum stock level and sit back.

In multiple channel organizations, because of the minimum stock level, the product selection offered in the online store can remain limited compared to the actual product range. Not presenting a wide variety of products on digital channels cause the product range to look way too narrow. As a result, a great deal of potential revenue can be lost. In order to help businesses disrupted by the effects of the Covid-19 pandemic, Inveon’s omnichannel commerce infrastructure inCommerce addresses this problem.

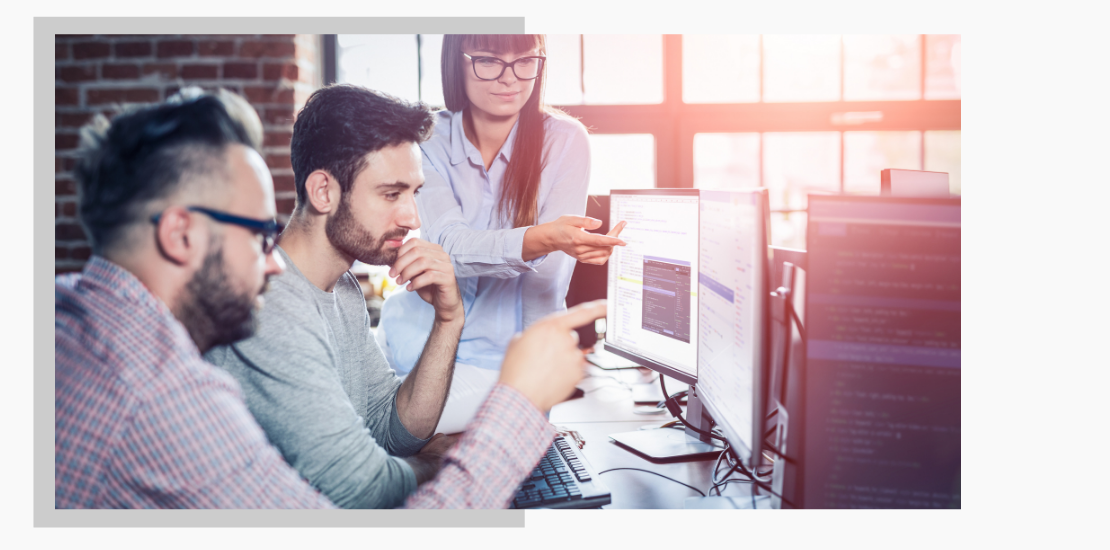

Consider the example of an Inveon customer, a leading garment brand. With the technical developments undertaken by Inveon, the physical store inventories of the brand were introduced to inCommerce’s admin panel. Through this first step, the brand team was able to use offline inventories for their online stores when required, through a single click. This way, the omnichannel stock management system was established, and incomplete purchases were eliminated. As a step further, an advanced omnichannel stock management project was developed in order to ensure a high level of inventory control.

Through this development, the brand was able to instantly control the minimum stock levels of different inventory units and decide which one will be available for sale. The reopening of offline stores shape operational focus and thanks to this system, if you are not satisfied with your turnover, you can instantly interfere with your store stocks, for example, you may offer outlet stores for sale and increase your turnover to the desired level. Or you realized that the last product left in the outlet’s inventory is causing problems and this situation puts a sudden increase in the burden on the customer service side. In this case, you can quickly intervene by closing your outlet stocks from the admin panel.

One of the most important features of this system is that it allows you to define different inventories as a group. In this way, the level of minimum stocks is determined not only for single items, but for the group, and offers more products for sale.

Another advantage of grouping different inventories is providing operational convenience by using an advanced shipment priority algorithm. This system allows you to minimize your logistics costs thanks to this algorithm that takes into account the minimum number of packages and the closest/available option to deliver the order while making a total evaluation of the offline store stocks and different warehouse products you have defined. In a scenario where more than one product will be shipped, the system first checks the primary prioritized group. If the stock level in this group does not allow a single package, the system scans the appropriate group according to the hierarchical order and tries to reach the minimum shipping unit. This capability not only reduces your operational costs, but also provides faster delivery capability and improves customer satisfaction and experience. At the same time, it provides a control that allows you to manage workforce distribution, physical costs and intensity that will affect your business performance in the background. You will have advanced management power by taking the inventory of your choice into use whenever you want or by taking it to passive status.

This operational capacity creates several different benefits for the brand and the end-users. For the end-users, it has successfully decreased the possibility of not being able to find the product they were looking for. Also, a wide range of different products became available in the online store. For the brand’s team, this system provided an opportunity to manage and check all online/offline stock levels through the admin panel without a need for additional knowledge or training.

A system like this allows you to easily manage the brand’s assets and increase efficiency via overcoming vital challenges. To take appropriate actions according to operational needs by simultaneously monitoring the workload and capacities of the logistics, customer services or accounting department, e-commerce operation progresses without interruption from the beginning until the end, all the while customer satisfaction increases. Thus, your e-commerce operations become easier to manage and in turn more profitable.

Efficient inventory management is an important topic for businesses who are preparing for a campaign period, launching a new line of products, trying to survive between the waves of the pandemic era or simply want to reveal an undiscovered potential through the usage of advanced omnichannel technology and take the brand’s performance to the next level.

With wider control, you can arrange the load on your different business units wisely. Increased inventory management efficiency will also increase the overall business efficiency. If you are ready to take action regarding this subject, check out more information about Inveon inCommerce now!